This site uses cookies to help deliver its services and analyse traffic.

Rivet Types and Sizes: Which One to Use for Your Project?

When it comes to fastening materials together securely, rivets are the go-to solution for DIY enthusiasts and construction professionals. Rivets provide a strong and permanent bond between materials, making them essential for many projects including both wood and metalwork. However, with a wide range of rivet types and sizes available, it can be overwhelming to determine which one is best suited for your specific project. Here at BS Fixings, we stock a wide array of rivets and so we have created this guide to provide you with the knowledge you need to make an informed decision.

What is a Rivet?

A rivet is a type of fastener that features a ‘factory head’ and long cylindrical shaft, with the head typically being larger than the diameter of the shaft. Unlike other types of fastenings that are fairly easy to remove, rivets are a permanent type of fastener. When they are inserted into a hole, the cylindrical shaft compresses and deforms to create a ‘shop head’. There a many different types of rivets, all of which are used in different ways, for example with a hammer or with an appropriate rivet tool/gun. Below we have listed the types of rivets you can find, and how they are used.

Types of Rivets

Rivets come in various types, each designed for specific projects and purposes. Here are some commonly used rivets:

Solid Rivets: solid rivets are the most traditional type of rivets, which are also referred to as round rivets. They consist of a single piece of metal that is hammered or pressed into place. They are highly durable and offer excellent strength, making them suitable for heavy-duty applications such as construction and structural work. Due to their design, they can easily be deformed using a hammer and are therefore great for people with limited tools.

Blind Rivets: also known as pop rivets, blind rivets are widely used for their versatility and ease of installation. They feature a mandrel that is pulled through the rivet body, causing it to expand and secure the materials together. Once the materials have been secured, you will hear a ‘popping’ sound, where the remaining mandrel snaps, leaving the rivet in place. Blind rivets are ideal for applications where access is limited to one side.

Drive Rivets: drive rivets, also called drive screws or split rivets, consist of a solid shank with a tapered end and a slotted head. They are inserted through pre-drilled holes and are driven into place using a hammer or mallet. Drive rivets are commonly used in woodworking and furniture assembly.

Tubular Rivets: tubular rivets are hollow and feature a solid head at one end. They are commonly used for joining metal sheets, leather, and fabrics. Tubular rivets provide a clean and aesthetically pleasing appearance, making them suitable for applications where visual appeal is important.

Split Rivets: also known as bifurcated rivets, split rivets are designed with a split end which allows the rivet to pierce through materials easily. When they are inserted, the split ends bend and hold materials together. These are generally more useful for light-duty projects such as repairs in wood, leather, and plastic.

Flush Rivets: finally, flush rivets have a countersunk design which ensures a flush and neat finish. Flush rivets are commonly used within the aerospace industry, to improve aerodynamics.

Selecting the Right Rivet Size

Grip Range: the grip range refers to the thickness of the materials being joined. It is essential to measure the total thickness of the materials to determine the appropriate rivet length. Using a rivet that is too short may not provide sufficient clamping force, whilst using a rivet that is too long can lead to an inefficient joint.

Diameter: the diameter of the rivet determines its strength. Larger diameter rivets offer higher shear and tensile strength, making them suitable for heavy-duty applications. However, it is important to ensure that the rivet diameter is compatible with the hole size for it to fit appropriately.

Head Style: rivets are available in various head styles, including round, countersunk, and dome. The choice of head style depends on the desired aesthetic appearance, as well as the functional requirements of the project.

Whether you're building furniture, repairing metalwork, or working on a construction project, choosing the right rivet will provide a secure and reliable bond. At BS Fixings, we offer a wide range of high-quality rivets in various types and sizes, ensuring you have the perfect fastening solution for your specific needs. Explore our rivet collection today and take your projects to new heights!

We stock 304 and 306 stainless steel rivets, as well as aluminium types too. With our large selection, you will be able to find a rivet that is suitable for the environment it is being used in. If you require further information about rivets or our product range, please call us on 03330 117818 and a member of our team will be happy to help!

Latest from BS Fixings

Banish the Grime in a Swipe: New UltraGrime Pro Multi-Use Clothwipes!

At BS Fixings, we understand that when you’re knee-deep in your trade, the last thing you want to worry about is the mess. That’s why we’re excited to introduce a...

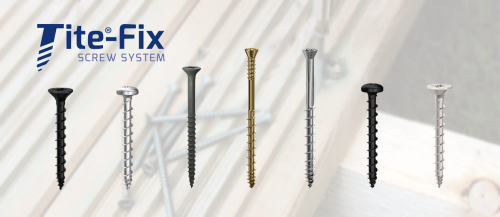

Continue readingIntroducing Tite®-Fix at BS Fixings

BS Fixings is proud to introduce yet another brand to our lineup - Tite®-Fix! This brand offers a range of high-quality screws designed for various applications, from tongue & groove...

Continue readingNew In! Rawlplug’s R-KEM2 Polyester Styrene-Free Resin

We're pleased to share something special with you – the Rawlplug R-KEM2 Polyester Styrene-Free Resin 300ml has just landed at BS Fixings! This ingenious resin is designed for use in...

Continue readingWhich Types of Screw are Best for Outdoor Use?

At BS Fixings, we understand the challenges posed by the great outdoors, especially when it comes to decking, fencing, installing outdoor ironmongery or even assembling garden furniture. That’s why we...

Continue readingHow Do I Choose the Right Size Drill Bit for a Wall Plug?

In this blog, we’re going to tackle another common question we hear in our community – how do I choose the right size drill bit for a wall plug? Choosing...

Continue readingWhat’s the Difference Between an Anchor Bolt and a Through Bolt?

When it comes to securing anything from the lightest of fixtures to the heftiest of machinery, the importance of choosing the right bolt cannot be overlooked. It’s the kind of...

Continue reading