When completing a construction or DIY project, the choice of screw might seem like a small detail, but it can have a huge impact on the outcome of your work. Self-drilling and self-tapping screws are two types that often cause confusion, even for the most experienced handymen and builders. In this blog, we’re going to explore these two screw types, helping you to understand their different features and applications.

Self-Drilling Screws

Self-drilling screws, commonly referred to as Tek screws, are easily recognisable by their distinctive drill-bit-shaped tip. This design enables the screw to create its own pilot hole as it’s driven into the material, thereby removing the need for pre-drilling. This feature is a significant time-saver, especially when numerous screws are required in a project, as the process of drilling each hole separately can be quite time-consuming and labour-intensive.

Characteristics of Self-Drilling Screws

- Drill-Bit Tip: the defining feature of self-drilling screws is their ability to drill their own pilot hole, which streamlines the installation process by merging drilling and fastening into one.

- Number System: these screws come with a number system ranging from 1 to 5, denoting the length and thickness of the drill points. This system helps users select the appropriate screw for different material thicknesses and types.

- Versatile Head Styles and Lengths: self-drilling screws are available in various lengths and head styles, including popular Phillips, Hex, and Square types. This ensures that they can cater to a broad range of projects and tools.

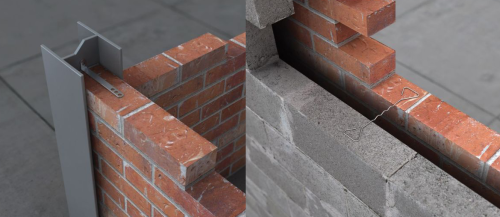

- Applications: these screws are perfect for fastening similar materials (such as metal to metal) and also different materials (like metal to wood). They are especially suitable for lighter gauge applications, although a #5 drill point screw can handle heavier-duty materials, such as half-inch thick steel sheets. Common uses include HVAC installations, steel framing, cladding and roofing, and general construction tasks.

Self-Tapping Screws

Self-tapping screws are designed to tap threads into the material it is driven into. Unlike self-drilling screws, self-tapping screws require a pilot hole to be drilled beforehand. This step is crucial for ensuring that the screw can efficiently cut or form threads into the material, which is essential for a secure and lasting hold.

Characteristics of Self-Tapping Screws

- Pilot Hole Requirement: one of the key differences between self-tapping and self-drilling screws is that self-tapping screws must be used with a pre-drilled pilot hole. This ensures that the screw can effectively tap into the material without causing damage or misalignment.

- Tip Designs: self-tapping screws are available with different tip designs, which determine the method of threading – either cutting or rolling the thread into the material. These different tips offer versatility in how the screw interacts with the material.

- Hole Size Importance: the size of the pilot hole is an important consideration. If the hole is too large, the screw will not fasten properly and won’t create an effective thread, leading to a weak hold. Conversely, if the hole is too small, the screw might split or crack the material.

- Applications: these screws are suitable for a wide range of materials, from metals and plastics to some forged materials like aluminium or iron. Their versatility makes them a popular choice for many construction and DIY projects. Common uses include fixing brackets to timber and ply, securing thin sheets of metal, and fixing into plastic housing.

It’s important to note that whilst all self-drilling screws are by nature self-tapping, the vice versa is not true, as not all self-tapping screws have self-drilling properties. This is crucial to remember in your project planning, as misjudging or substituting one for the other could lead to setbacks.

Choosing between self-drilling and self-tapping screws depends on your project's specific requirements. Consider the material, size, and application to ensure you select the right screw. At BS Fixings, we offer a wide range of both self-drilling and self-tapping screws to cater to all your fixing and fastening needs. Please feel free to browse our extensive product catalogue today or contact us on 03330 117818 for more information.