Do you know the importance of choosing the correct type of screw? Whether you’re fixing a large timber frame or mounting a shelf on a masonry wall, you will more than likely need a variety of screws for your project. Screws that are inadequate or not suitable for your project will result in a low-quality finish, that will not perform well. For example, screws can become loose, they can cause splitting, and in some cases, the threads can strip when driven into the wrong materials.

In this blog post, we explain why selecting the right screw for your construction or DIY task is essential. There are several things to consider when searching for screws, including the screw material, the thickness of the surface material, screw features such as length, drive, and threads - the list goes on! Find below a quick guide on how to choose the most appropriate screw for your project.

Common screw types

Wood Screws – as you might have guessed, wood screws are designed to be used with wood. They generally have a partial thread which stops the material from splitting when the screw is driven in.

Drywall Screws – drywall or plasterboard screws tend to be long and sharp, to pierce through hollow materials easily.

Self-drilling Screws – these screws are manufactured to drill through metal and plastic. They are commonly used in the automotive and construction industries.

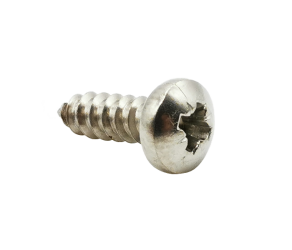

Self-tapping Screws – self-tapping screws tap their own threads in materials such as wood, plastic and metal.

Machine Screws – machine screws generally have thinner threads compared to other screws. They are used with pre-drilled tapped holes to fasten metal parts together.

Popular drives

Phillips – Phillips screw heads are well-liked due to their effectiveness and ease of use. They can be used with a screwdriver or drill.

Slotted – this is one of the simplest types of drives, that is used for smaller projects.

Torx – Torx drives provide greater stability for the user, with multiple rounded points to stop the screwdriver from slipping.

Pozi – the Pozi drive is the new and improved Phillips, that offers better stability.

Screw heads

Countersunk – countersunk screw heads are one of the most common head types, designed to provide a flush and smooth finish. They are generally used with screws created for wood and plaster.

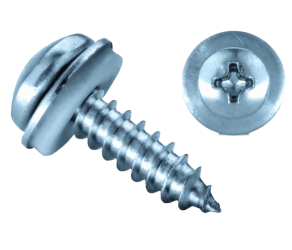

Button – button head screws have a cylindrical shape, which offers a flush finish similar to the countersunk. Most button heads are accompanied with a washer for a clean look.

Hexagonal – hex heads have a six-sided head, that provides extra strength. Their more rigid structure creates a stronger clamping bond, as they cover a larger surface area.

Pan – these are a common type of head, which are non-countersunk. Pan head screws are often used for securing metal materials.

Bugle – bugle heads tend to be used with self-drilling drywall screws. They have a countersunk shape, which offers a secure fixing with plasterboard materials.

Screw material

Stainless steel – many screws are manufactured out of stainless steel for their corrosion resistance properties and overall strength.

Zinc plated – screws that are coated in zinc also have excellent corrosion resistance, typically used for wood screws.

Phosphate – phosphate screws are black in colour, and commonly used with drywall.

Brass – brass screws are generally used indoors, as they do not have a coating to resist rusting. They are used for simple projects such as furniture and cabinets.

Here at BS Fixings, we stock screws with all of these features, so make sure you consider all of the above. With over 8 years of experience in the fixing and fastening industry, you can rely on us for top-quality products that will serve you well! We are proud to stock items from industry leaders such as Goebel and SPAX, to deliver our customers the very best products. Please feel free to browse our fixing products on our website or if you require more information, contact us today and we will be happy to help.