When it comes to fixings and fasteners, precision and compatibility are key. Screws are one such fixing that are essential in a range of industries, including construction, manufacturing, and assembly, playing an important role in joining and mounting materials. Two of the most common screw head designs are Phillips and Pozi. Although these two head types might appear similar at first glance, understanding their unique features is important for ensuring effective application and avoiding damage to both your tools and the screw itself.

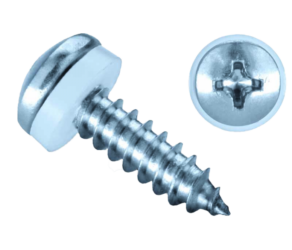

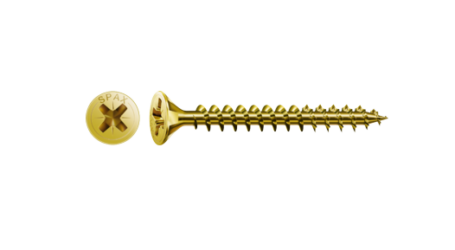

Phillips Screws

Invented in the 1930s by Henry F. Phillips, this design features a cross-shaped slot that allows for more grip compared to flat head screws. Phillips heads are easy to install but have a low torque capacity, making them suitable for tasks where a tight fit is crucial. Phillips screws are frequently used in electronics, appliances, and automotive applications, where precision is not as important. Unfortunately, Phillips heads are notorious for their tendency to ‘cam out’ under excessive torque, which was originally intended to prevent over-tightening but can be a drawback when more force is required.

Pozi Screws

Pozi screw heads were introduced in the 1960s to overcome some of the limitations of the Phillips design. They feature a similar cross-like design but have an additional set of markings between the arms at 45-degree angles. This design is instrumental in reducing cam-out, allowing for higher torque to be applied without the screwdriver slipping out. The Pozi head is recognisable by the markings of a “+” sign with a circle around it and tends to have deeper and sharper grooves compared to Phillips screws, improving their resistance to stripping. These screws are versatile, commonly employed in furniture, cabinetry, and household appliances. Their high torque capacity also makes them suitable for heavy-duty applications.

Key Differences:

- Cam-Out Resistance: Pozi screws are designed to resist camming out better than Phillips, making them suitable for projects that require higher torque.

- Tool Compatibility: whilst a Phillips screwdriver can fit into a Pozi screw head, using the correct Pozi screwdriver is important for optimal performance and to avoid damage.

- Visual Identification: the additional grooves and the distinctive markings make Pozi screws easily distinguishable from Phillips types.

Updated Considerations

With advancements in fastener technology, the choice between Phillips and Pozi screw heads may also depend on the specific requirements of the task, such as material, environment, and accessibility. Manufacturers continue to innovate in materials and designs, offering solutions tailored to diverse needs.

Whether you're assembling furniture, working on a vehicle, or engaging in intricate electronic repairs, knowing the difference between Phillips and Pozi screw heads can make a huge impact on your work. Just remember, the main difference is, Pozi screws are better suited for heavy-duty tasks where a secure fit is necessary, whilst Phillips screws are more appropriate for less demanding applications. If you would like further assistance in choosing the right type of fastening for your project, please contact us on 03330 117818 or email info@bsfixings.co.uk and a member of our team will be happy to help.