Screws are an essential part of many people’s lives, from construction projects to everyday repairs, they are used for a wide range of purposes. Whilst most people are familiar with screws and what they do, very few understand the science behind how they work, so we have written this blog post to help you out! We are going to deep dive into the world of screws, looking at their design and function, as well as the different varieties that are available on the market.

The anatomy of a screw

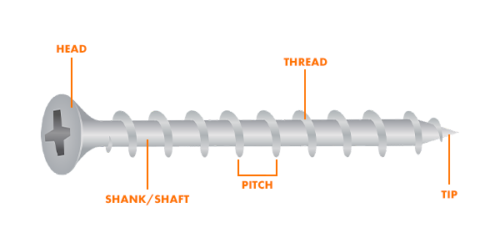

Before we delve into the science behind screws, it's important to understand their basic anatomy. It’s pretty easy to visualise what a screw looks like, but did you know each part has a different name? Screws are relatively simple, consisting of four main parts: the head, shank/shaft, thread, and tip.

The head is the part of the screw that is turned to drive it into the surface and is available in many different shapes, such as hexagonal, flat, and pan. The next section of the screw is the shank, which connects the head of the screw to the tip. At some point along the shank, the thread will start, which is the raised spiral exterior that wraps around the length of the screw. The thread is probably the most important element, as it allows the screw to grip the material that is being driven into. When the screw is turned, the ridges of the thread push against the material, creating friction that holds the screw in place. Finally, the tip of the screw is the initial point of contact between the fixing and the surface material. There are three main types of tips: thread-forming, thread-cutting, and self-drilling. The choice of tip will depend on the material that is being used, for example, wood screws will generally have a sharp, self-drilling tip that will prevent wooden surfaces from splitting when being driven into.

The physics behind how they work

How screws work is based on two simple systems, the inclined plane and the lever. The incline plane relates to the thread of the screw, which when turned, creates a ‘ramp’ that lifts the screw and pulls it into the material underneath. The thread or incline plane can either be along the whole length of the shaft or partially, and the distance between each thread can also differ. The lever in a screw is the distance between the centre of the screw and the point where it contacts the material. This distance is called the pitch, which will produce a coarse or fine thread screw. Coarse thread screws have a larger pitch whilst fine thread screws have a smaller pitch. The pitch determines the amount of force needed to turn the screw.

The role of friction

Friction and the distribution of force play a critical role in the physics of a screw – it is effectively how they work! When screws are rotated in a circular motion, the threads create torque which positions the screw into place as it is being driven in. It does this by transferring the torque into a linear force which inserts the screw level along its axis. As a result of this, the position of the threads can affect the holding power of the screw, as the distribution of force will differ.

Fine thread screws have a much higher tensile strength compared to coarse screws, as there is a larger stress area for the material to grip onto. Therefore, fine thread screws are commonly used for specific projects such as fastening into metal. Coarse thread screws are perfect for most tasks and are generally a great multipurpose fixing.

The angle of the screw

The angle of the screw thread, also known as the helical angle, is another crucial feature. The helical angle is the angle at which the threads wrap around the screw. In general, the larger the angle is, the easier it is to drive the screw into the surface. However, it also means there is less contact area between the screw and the surface, which can reduce the strength of the connection. With this in mind, fine thread screws have greater contact with the surface material and will less likely become loose over time.

Different Screw Heads

Screw heads come in a variety of shapes and sizes, each with their own advantages and disadvantages. Here are some of the most common screw heads and their uses:

Flat Head: flat head screws have a countersunk head that sits flush with the surface. These are commonly used in woodworking and other applications where a clean, flat finish is desired.

Pan Head: pan head screws have a rounded, slightly raised head. These are commonly used in electrical and automotive industries for securing metal.

Round Head: round head screws have a rounded head that protrudes slightly above the surface. These are commonly used in construction and general DIY tasks where a strong, secure hold is needed.

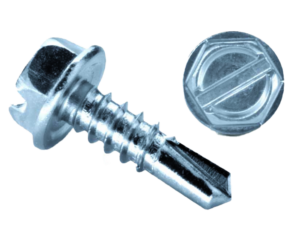

Hex Head: hex head screws have a hexagonal head that can also be turned with a wrench or pliers. These are commonly used when a higher force is needed, as their larger surface area ensures a stronger holding power.

Phillips Head: phillips head screws have a cross-shaped head that requires a Phillips screwdriver to turn. These are commonly used in woodworking and other general fastening tasks.

Understanding the physics behind screws can help you find the right screw for your job and how to use it effectively. Here at BS Fixings, we stock an abundance of screws on our website, and it can be tricky to find the most suitable one for your project. However, with a better understanding of how they work, choosing the right one should now be a breeze! If you require additional assistance or need more information about the fixings we stock, our team of experts are always on hand to help. Simply call us on 03330 117818 and we will be happy to answer any questions you might have.