This site uses cookies to help deliver its services and analyse traffic.

What is the Difference Between Type 2 and Type 4 Wall Ties?

If you’re struggling to find the right wall tie for your construction project, you are not alone. Wall ties, essential for the structural integrity of buildings can often lead to confusion, as there are so many types and designs to choose from. With various types available, each designed for specific conditions and applications, deciding on the right one can be a daunting task. In this blog, we are here to guide you through the differences between common Type 2 and Type 4 wall ties, so you can make the correct choice for your next project!

Understanding Wall Ties

Before we explore Type 2 and Type 4 wall ties, it's important to understand the purpose of wall ties, to ensure you are utilising them effectively. Also known as ‘brick ties’, wall ties serve as the linchpin in connecting the inner and outer leaves of a cavity wall. Their primary function is to ensure that the cavity wall behaves as a coherent unit, maintaining structural integrity and resilience against a range of forces, preventing the two leaves from separating or bulging. Some forces include wind pressure, thermal movement, or differential settlement, which can compromise the wall’s structural soundness and, consequently, the safety of the building.

The reason wall ties are divided into different ‘Types’ stems from the variety of conditions and requirements different buildings face. From residential homes to towering commercial buildings, each structure has its unique demands based on factors like height, geographical location, and exposure to external elements. For example, a building in a coastal area might require wall ties with superior corrosion resistance due to the salty air, whereas a structure in an area prone to high winds might need ties that can withstand substantial force. Moreover, the cavity width between the inner and outer walls can vary from one project to another, necessitating different types of ties to bridge these gaps effectively.

Type 2 Wall Ties

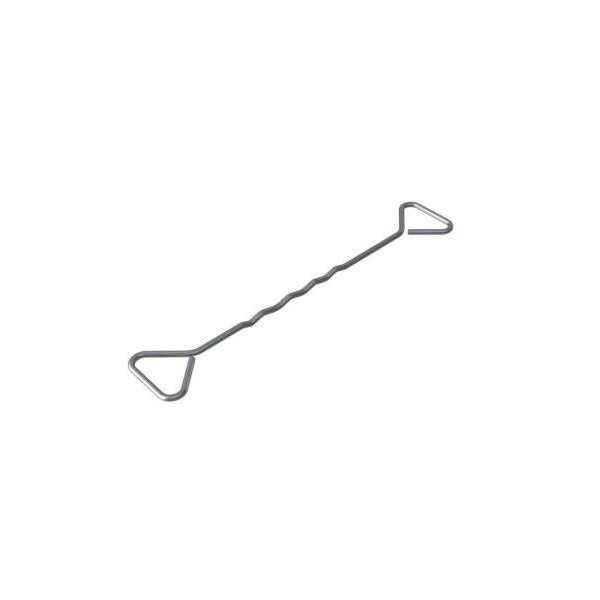

Type 2 wall ties are the go-to choice for many builders due to their versatility and general-purpose design. They are typically manufactured from heavy gauge wire or stainless steel and are designed to offer a balance of strength, flexibility, and durability. They are suitable for use in most domestic and many commercial buildings, where standard loading and environmental conditions apply, particularly those with a maximum height of 15 meters and located on flat sites where the basic wind speed does not exceed 31m/s. The key characteristics of Type 2 ties include their resilience against corrosion, which makes them an excellent choice for external walls, and their ability to accommodate slight movements within the wall without compromising structural integrity.

The design of Type 2 ties typically includes a debonding mechanism to prevent moisture from travelling across the tie, which is essential for maintaining the integrity of cavity walls. They are also available with clips to secure insulation within the cavity, ensuring that the building is not only structurally sound but also energy-efficient.

Type 2 ties are also recognised for their ease of installation, which can be beneficial in projects with tight deadlines or where labour costs are a concern.

Type 4 Wall Ties

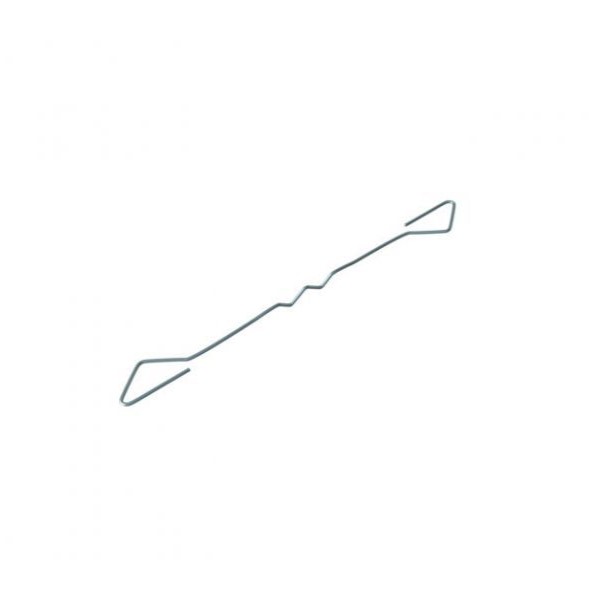

Type 4 wall ties, on the other hand, are lighter in design and are often chosen for their flexibility. They are most commonly used in box-form domestic dwellings with inner and outer leaves of similar thicknesses and tend to be used in areas that are sheltered or less exposed to severe weather conditions. They are generally suitable for buildings with a maximum height of 10 metres and ideal for flat sites in towns and cities where the basic wind speed is up to 27m/s.

The lightweight nature of Type 4 ties makes them less suitable for heavy-duty applications but perfect for residential projects where the structural demands are not as rigorous. They are also compliant with standards for cavity masonry separating walls, which means they can be used with all approved robust details, eliminating the need for pre-completion sound testing.

The main advantage of these ties lies in their cost-effectiveness and the practicality of installation. They are an economical choice for projects where budget constraints are tight, but where quality and reliability cannot be compromised.

Key Differences Between Type 2 and Type 4 Wall Ties

Material and Durability

The most apparent difference between Type 2 and Type 4 wall ties is the material which they are made from. Type 2 ties are usually made from stainless steel, offering durability and corrosion resistance. This makes them suitable for a broader range of environments, including coastal areas where salt can accelerate corrosion. Type 4 ties, generally manufactured from pre-galvanised mild steel, whilst still durable, are generally considered less resilient in harsh conditions.

Application and Performance

Type 2 ties are engineered for medium to heavy-duty applications, providing the strength needed for commercial buildings or homes in high-wind areas. Their design accommodates natural building movements without losing grip or stability. Type 4 ties, with their lighter design, are intended for lighter-duty applications, making them ideal for low-rise, residential projects where extreme conditions are not a concern.

Cost and Installation

When it comes to cost, Type 4 wall ties usually offer a more budget-friendly solution, reflecting their application in less demanding environments. However, it's essential to consider the long-term implications of your choice, as the superior corrosion resistance and durability of Type 2 ties may offer better value over the lifespan of a building. Installation ease is another consideration, with both types designed for straightforward installation, though the lighter weight of Type 4 ties might slightly edge out in terms of handling.

Making the Right Choice

Choosing between Type 2 and Type 4 wall ties comes down to understanding the specific needs of your project. Factors such as the building's location, the environmental conditions it will face, and the structural demands of the construction should all influence your decision. At BS Fixings, we're committed to providing our customers with high-quality, reliable wall ties that meet the different needs of modern construction projects. Please feel free to browse our extensive wall tie range on our website or if you require some expert advice, don’t hesitate to get in touch with a member of our team on 03330 117818!

Latest from BS Fixings

Banish the Grime in a Swipe: New UltraGrime Pro Multi-Use Clothwipes!

At BS Fixings, we understand that when you’re knee-deep in your trade, the last thing you want to worry about is the mess. That’s why we’re excited to introduce a...

Continue readingIntroducing Tite®-Fix at BS Fixings

BS Fixings is proud to introduce yet another brand to our lineup - Tite®-Fix! This brand offers a range of high-quality screws designed for various applications, from tongue & groove...

Continue readingNew In! Rawlplug’s R-KEM2 Polyester Styrene-Free Resin

We're pleased to share something special with you – the Rawlplug R-KEM2 Polyester Styrene-Free Resin 300ml has just landed at BS Fixings! This ingenious resin is designed for use in...

Continue readingWhich Types of Screw are Best for Outdoor Use?

At BS Fixings, we understand the challenges posed by the great outdoors, especially when it comes to decking, fencing, installing outdoor ironmongery or even assembling garden furniture. That’s why we...

Continue readingHow Do I Choose the Right Size Drill Bit for a Wall Plug?

In this blog, we’re going to tackle another common question we hear in our community – how do I choose the right size drill bit for a wall plug? Choosing...

Continue readingWhat’s the Difference Between an Anchor Bolt and a Through Bolt?

When it comes to securing anything from the lightest of fixtures to the heftiest of machinery, the importance of choosing the right bolt cannot be overlooked. It’s the kind of...

Continue reading