-

Helical Remedial Wall Ties - 8mm Diameter - Box of 50

Helical Remedial Wall Ties - 8mm Diameter - Box of 50Sold in boxes of 50

Various sizes available

Tool for installation sold separately - Drive Tie Setting Tool

Learn MoreFrom £49.92 £41.60

Sales: 03330 117818 | Support: 03330 117817

Helical Wall Ties

Advanced Helical Wall Ties for Cavity Wall Construction and Structural Remediation

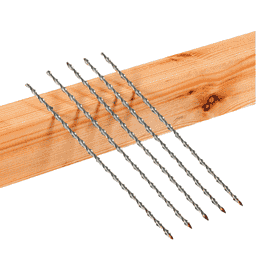

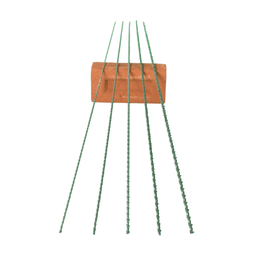

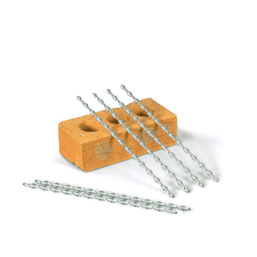

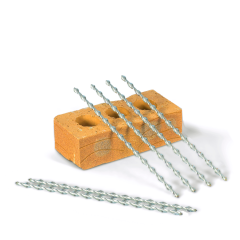

Our helical wall ties provide a high-performance fixing solution for both new cavity wall construction and remedial reinforcement of failing masonry. Manufactured from work-hardened austenitic stainless steel, these precision-engineered helical ties deliver outstanding axial strength, resilience and durability in all common masonry materials.

The helical form allows the tie to cut into the brick or block as it is driven, creating a deep, reliable mechanical interlock. This makes helical ties ideal for stabilising cavity walls where traditional ties have corroded, failed or were inadequately installed.

How Helical Wall Ties Work

Helical wall ties use a spiral, work-hardened stainless steel profile that anchors securely into both masonry leaves through rotational or hammer-driven installation. As the tie is driven into the substrate, the helical fins create:

-

A strong torsional lock

-

High pull-out resistance

-

Reliable load distribution

This design enables the tie to accommodate differential movement, thermal expansion and structural settlement without transferring stress to the brickwork. The result is a flexible yet extremely strong wall tie suitable for modern building standards and complex remedial scenarios.

Key Performance Benefits

Exceptional Tensile Strength

Work-hardened stainless steel provides excellent axial load capacity and superior fatigue resistance. This makes helical wall ties ideal for stabilising walls subject to wind loading, vibration or thermal movement.

Secure Anchoring in Weak or Deteriorated Masonry

The helical design achieves strong anchorage in:

-

Perished or low-density brick

-

Aircrete and lightweight block

-

Rubble-filled walls

-

Mixed or variable substrates

This is why helical ties are a preferred choice for remedial wall tie replacement in older buildings, housing stock upgrades and conservation areas.

Corrosion-Resistant Stainless Steel

Manufactured from stainless steel, helical ties deliver long-term resistance to corrosion, moisture and chemical attack, making them suitable for buildings exposed to coastal conditions, pollution or high moisture levels.

Low-Disruption Installation

Helical ties are quick to install using either:

-

An SDS drill adaptor

This minimises drilling, reduces dust and noise, and allows installation in occupied buildings with minimal disruption.

Typical Applications

Helical wall ties are commonly used for:

-

New build cavity walls

-

Remedial wall tie replacement where ties have corroded or failed

-

Crack stitching and façade stabilisation

-

Securing external leaf masonry to internal load-bearing structures

-

Heritage masonry reinforcement where minimally invasive methods are required

-

Upgrading structural integrity in older housing stock

They are suitable for cavity widths typically ranging from 50mm to 150mm, depending on tie length.

Choosing the Correct Wall Tie Length

For safe installation, each tie must embed at least 75mm into both inner and outer leaves. Tie length is calculated as:

Cavity width + 150mm = minimum tie length

Examples:

-

50mm cavity = 200mm tie

-

100mm cavity = 250mm tie

-

150mm cavity = 300mm tie

If you want, I can build this into a table for your category page.

Why Helical Wall Ties Outperform Traditional Ties

Compared with older-style wire or mechanical ties, helical ties offer:

-

Higher pull-out performance

-

Fast, clean installation

-

Better performance in weak masonry

-

No resins, plates or large holes required

-

Flexibility to allow natural building movement

-

Outstanding resistance to corrosion and fatigue

This modern approach to tying masonry improves the structural longevity of both new and existing buildings.

Key Features at a Glance

-

Work-hardened stainless steel helical profile

-

High tensile and axial load performance

-

Secure fixing in weak or variable substrates

-

Fast installation using SDS or hammer tools

-

Excellent mechanical anchorage without resin

-

Suitable for new build and remedial works

-

Long-term corrosion resistance (304/316 stainless steel)

-

Available in a full range of lengths to suit cavity depth