This site uses cookies to help deliver its services and analyse traffic.

Coil Mesh: A Step-by-Step Guide

Coil mesh, one of the latest products to be added to the BS Fixings collection, is designed to be incorporated into masonry panels, increasing their rigidity and giving extra control over cracking. Here is a step-by-step guide on how to use it for optimal results.

- Make sure that the wall is sound and free from any moisture-related issues

- Use a pH-neutral cleaner to wash the surface before rinsing with clean water

- Allow the wall to air-dry for 24 hours. Alternatively, pat dry with a cloth and wait two hours for drying to complete

- If there is paint on the wall surface, roughen it by sanding with medium-grit sandpaper. Paint can interfere with the adhesion qualities of plaster or mortar that is placed against mesh after it is mounted: the sanding process removes this interfering finish

- Use a clean, dry cloth to wipe away any residue after sanding

- Measure the wall and cut the mesh to the required size using snips. Be sure to wear protective gloves (also available from the BS Fixings website). If using multiple sheets of mesh to cover the surface, allow for overlapping edges when measuring and cutting. Where pieces meet with a horizontal seam, an overlap of around 5cm is required: for vertical seams, allow 15cm of overlap

- With the diamonds of the mesh pointed upward, hold the piece against the wall. Use concrete nails to secure the mesh in place, driving them through the mesh into the wall. Nails should be spaced at around 15cm, using staggered rows. Drive the nails through any overlapping edges to prevent them from curling upward

- Continue the surface onto adjacent walls, bending the mesh around corners as required. Be sure to extend the sheet at least 15cm after rounding a corner, continuing with normal overlapping spacing with the next sheet

Coil mesh from BS Fixings is available in a range of sizes in either galvanised or stainless steel. Find out more details on the product page of our website, where you can also download a full data sheet in .pdf format.

Latest from BS Fixings

Introducing Tite®-Fix at BS Fixings

BS Fixings is proud to introduce yet another brand to our lineup - Tite®-Fix! This brand offers a range of high-quality screws designed for various applications, from tongue & groove...

Continue readingNew In! Rawlplug’s R-KEM2 Polyester Styrene-Free Resin

We're pleased to share something special with you – the Rawlplug R-KEM2 Polyester Styrene-Free Resin 300ml has just landed at BS Fixings! This ingenious resin is designed for use in...

Continue readingIntroducing the Premier Volkel Range!

At BS Fixings, we are proud to stock a fantastic range of products from many well-known names in the DIY and construction market, and we’re excited to extend our catalogue...

Continue readingHow Do I Choose the Right Size Drill Bit for a Wall Plug?

In this blog, we’re going to tackle another common question we hear in our community – how do I choose the right size drill bit for a wall plug? Choosing...

Continue readingWhat’s the Difference Between an Anchor Bolt and a Through Bolt?

When it comes to securing anything from the lightest of fixtures to the heftiest of machinery, the importance of choosing the right bolt cannot be overlooked. It’s the kind of...

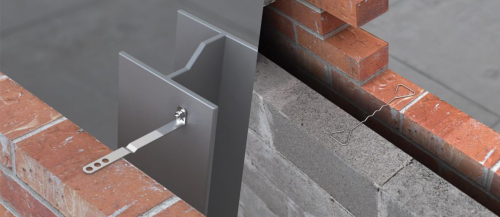

Continue readingWhat is the Difference Between Type 2 and Type 4 Wall Ties?

If you’re struggling to find the right wall tie for your construction project, you are not alone. Wall ties, essential for the structural integrity of buildings can often lead to...

Continue reading