This site uses cookies to help deliver its services and analyse traffic.

Carbon Emissions are Dropping Within the Steel Industry

Wood Mackenzie, a leading Verisk business, expects that the carbon emissions produced by the steel industry will fall by 30% by 2050, compared to 2021 levels.

Despite the challenge of decarbonising the steel industry, the carbon emissions are slowly being reduced and we can see some progression. As we all continue to aim for a greener future, the steel industry must follow suit and adopt green goals and low-emission alternatives.

One of the main reasons for the high emissions in the steel industry is the dependency on blast furnaces which are incredibly polluting. To discourage companies and steelmakers from using this process, electric arc furnaces (EAF) are being promoted. The EAF process is ¾ less emission-intensive than the blast furnace route. According to Woodmac, by 2050 around 48% of the world’s crude steel will be produced by EAF.

The research director of Woodmac, Malan Wu stated: “The global share of electric arc furnace (EAF) in steelmaking is rising with policy shifts and increasing focus on scrap use. Basic oxygen furnace (BOF) output will decline 0.5% annually until 2050, whereas EAF output could increase 2.3% yearly in the same period.”

As early as 2027, the steel industry is also expected to use hydrogen in steel production. Hydrogen-based steel production will account for 10% of the total steel output by 2050, with the EU at the forefront.

China is one of the world’s biggest producers of steel metal, accounting for over 2 billion tonnes of greenhouse gas emissions last year alone. However, despite being one of the largest contributors of carbon emissions, they are expected to be one of the first countries to reduce emissions entirely. China has worked hard to meet its carbon commitments and greener goals by cutting 30 million tonnes of crude steel production in 2021. Woodmac predicts that China’s emissions will halve between now and 2050, due to the decline in steel output.

However, many other rich economies such as the UK, US, EU, Japan, and Korea, will need to put in more effort to cut emissions, due to them being developing countries or small steel contributors. By switching to EAF, these economies are estimated to reduce carbon emissions by almost 50%, whether they decrease or increase their steel output.

Unfortunately, for regions such as India and Southeast Asia, their emission output will increase as their crude steel production continues to rise through the traditional blast furnace. Decarbonisation goals and commitments will intensify for these countries at a later date.

Hopefully, with EAF and greener low-emission alternatives, we will be able to achieve a more sustainable and eco-friendly future within the steel industry.

Latest from BS Fixings

Introducing Tite®-Fix at BS Fixings

BS Fixings is proud to introduce yet another brand to our lineup - Tite®-Fix! This brand offers a range of high-quality screws designed for various applications, from tongue & groove...

Continue readingNew In! Rawlplug’s R-KEM2 Polyester Styrene-Free Resin

We're pleased to share something special with you – the Rawlplug R-KEM2 Polyester Styrene-Free Resin 300ml has just landed at BS Fixings! This ingenious resin is designed for use in...

Continue readingIntroducing the Premier Volkel Range!

At BS Fixings, we are proud to stock a fantastic range of products from many well-known names in the DIY and construction market, and we’re excited to extend our catalogue...

Continue readingHow Do I Choose the Right Size Drill Bit for a Wall Plug?

In this blog, we’re going to tackle another common question we hear in our community – how do I choose the right size drill bit for a wall plug? Choosing...

Continue readingWhat’s the Difference Between an Anchor Bolt and a Through Bolt?

When it comes to securing anything from the lightest of fixtures to the heftiest of machinery, the importance of choosing the right bolt cannot be overlooked. It’s the kind of...

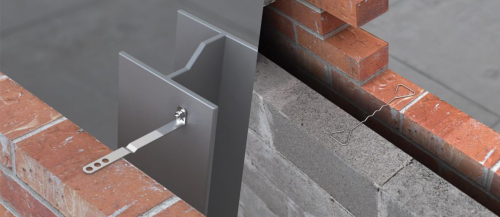

Continue readingWhat is the Difference Between Type 2 and Type 4 Wall Ties?

If you’re struggling to find the right wall tie for your construction project, you are not alone. Wall ties, essential for the structural integrity of buildings can often lead to...

Continue reading